The control module power circuit is the lifeline of your vehicle's electronic systems, serving as the crucial link between the battery and the various control modules that manage everything from engine performance to climate control. As vehicles become increasingly sophisticated, the importance of a well-functioning control module power circuit cannot be overstated. In this comprehensive guide, we'll delve deep into the intricacies of this vital system, explore common issues, and provide expert solutions to keep your vehicle running smoothly.

| Component | Function | Common Issues |

|---|---|---|

| Battery | Power source | Corrosion, low charge |

| Fuses | Circuit protection | Blown fuses, loose connections |

| Wiring harness | Power distribution | Frayed wires, loose connections |

| Control modules | System management | Software glitches, hardware failure |

The Anatomy of a Control Module Power Circuit

Before we dive into troubleshooting, it's essential to understand the components that make up a control module power circuit. This knowledge will serve as the foundation for diagnosing and resolving issues effectively.

Power Source: The Battery

At the heart of the control module power circuit lies the vehicle's battery. This 12-volt powerhouse is responsible for providing the initial surge of electricity needed to start the engine and maintain power to critical systems when the engine is off. A healthy battery is crucial for the proper functioning of all control modules.

Distribution Network: Wiring Harness and Fuses

The power from the battery is distributed throughout the vehicle via a complex network of wires, collectively known as the wiring harness. This intricate web of conductors ensures that each control module receives the appropriate voltage and current. Fuses are integrated into this network to protect sensitive electronic components from power surges and short circuits.

The Brain: Control Modules

Various control modules, such as the Engine Control Module (ECM), Body Control Module (BCM), and Transmission Control Module (TCM), are the recipients of this carefully managed power supply. These sophisticated computers rely on a stable and clean power source to function correctly and make split-second decisions that affect your vehicle's performance, safety, and comfort.

Common Issues Plaguing Control Module Power Circuits

Now that we understand the components, let's explore the most frequent problems that vehicle owners encounter with their control module power circuits. Identifying these issues early can save you from costly repairs and potential breakdowns.

Voltage Fluctuations: The Silent Killer

Voltage fluctuations are perhaps the most insidious problem affecting control module power circuits. These can be caused by a failing alternator, a weak battery, or corroded connections. Symptoms may include:

- Intermittent electrical issues

- Flickering lights

- Unexplained warning lights on the dashboard

- Difficulty starting the engine

Left unchecked, voltage fluctuations can lead to premature failure of control modules and other electronic components.

Wiring Woes: Frayed Nerves of Your Vehicle

The wiring harness is subjected to extreme conditions, including heat, vibration, and exposure to the elements. Over time, this can lead to:

- Frayed or broken wires

- Loose connections

- Corrosion at connection points

These issues can cause intermittent power supply to control modules, resulting in erratic behavior or complete failure of certain vehicle systems.

Fuse Failures: When Protection Becomes a Problem

While fuses are designed to protect your vehicle's electrical system, they can sometimes be the source of issues. Common fuse-related problems include:

- Blown fuses due to power surges or short circuits

- Corroded fuse connections

- Improperly rated fuses

A blown fuse can cut power to critical control modules, causing system failures and potentially leaving you stranded.

Diagnosing Control Module Power Circuit Issues

Identifying problems with your control module power circuit requires a systematic approach. Here's a step-by-step guide to help you pinpoint the source of your electrical woes:

Step 1: Visual Inspection

Begin with a thorough visual inspection of your vehicle's electrical components:

- Check the battery terminals for corrosion or loose connections

- Inspect visible wiring for signs of wear, fraying, or damage

- Examine fuse boxes for any signs of melting or discoloration

Step 2: Battery Health Check

A weak or failing battery can wreak havoc on your control module power circuit. Use a multimeter to check the battery voltage:

- With the engine off, a healthy battery should read between 12.4 and 12.7 volts

- With the engine running, the voltage should be between 13.7 and 14.7 volts

If the readings fall outside these ranges, your battery or alternator may be the culprit.

Step 3: Fuse Inspection

Carefully inspect all fuses related to the control modules:

- Use your vehicle's manual to locate all relevant fuse boxes

- Visually check each fuse for signs of failure

- Use a multimeter to test suspect fuses for continuity

Step 4: Wiring Continuity Test

If the above steps don't reveal the issue, you may need to perform a continuity test on the wiring:

- Disconnect the battery to ensure safety

- Use a multimeter to check for continuity between power sources and control modules

- Pay special attention to ground connections, as these are often overlooked

This step may require advanced knowledge and tools, so consider consulting a professional if you're unsure.

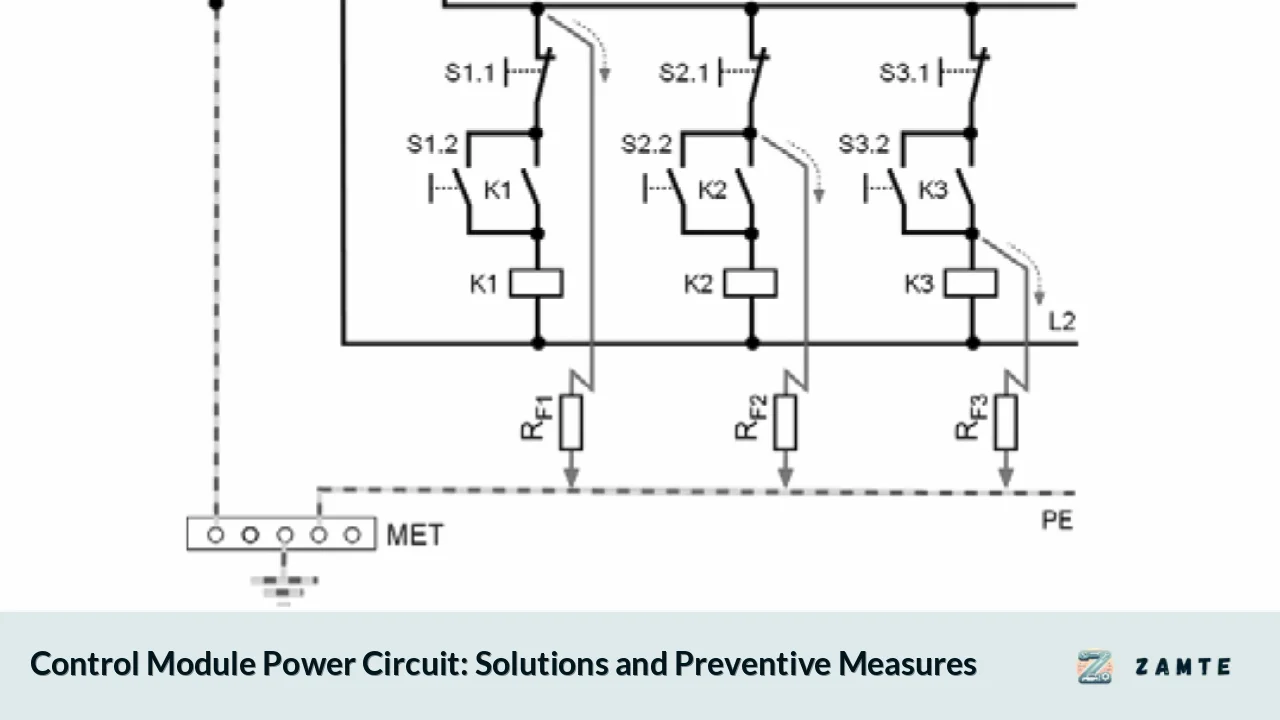

Solutions and Preventive Measures

Once you've identified the issue with your control module power circuit, it's time to implement solutions and take preventive measures to avoid future problems.

Addressing Voltage Fluctuations

To combat voltage fluctuations:

- Replace a weak or failing battery

- Have your alternator tested and replaced if necessary

- Clean and tighten all battery connections

- Consider installing a voltage stabilizer for sensitive electronic components

Wiring Repairs and Upgrades

To address wiring issues:

- Replace any frayed or damaged wires

- Use heat-shrink tubing to protect repaired connections

- Consider upgrading to higher gauge wires for critical circuits

- Apply dielectric grease to connections to prevent corrosion

Fuse Maintenance and Replacement

To ensure proper fuse protection:

- Replace blown fuses with ones of the correct amperage

- Clean fuse box connections with electrical contact cleaner

- Consider upgrading to circuit breakers for critical systems

Regular Maintenance: The Key to Longevity

Implementing a regular maintenance schedule is crucial for preventing control module power circuit issues. Here are some best practices:

- Perform monthly visual inspections of your vehicle's electrical system

- Have your battery and alternator tested annually

- Keep your vehicle's interior and engine bay clean and dry to prevent corrosion

- Address any electrical issues promptly to prevent cascading failures

When to Seek Professional Help

While many control module power circuit issues can be diagnosed and resolved by savvy DIY enthusiasts, there are times when professional intervention is necessary:

- If you're uncomfortable working with electrical systems

- When diagnostic tools indicate a problem with a specific control module

- If you've performed basic troubleshooting but the issue persists

- When dealing with hybrid or electric vehicles, which have high-voltage systems

Remember, the cost of professional diagnosis is often far less than the expense of replacing damaged components due to misdiagnosis or improper repairs.

"I had intermittent electrical issues with my car for months. Lights flickering, radio cutting out, you name it. Turned out to be a failing alternator that was causing voltage fluctuations. Once replaced, all my problems disappeared. Don't ignore the small stuff – it can lead to big headaches!"

The Future of Control Module Power Circuits

As automotive technology continues to evolve, so too will control module power circuits. Here are some trends to watch:

- Higher voltage systems: Many manufacturers are moving towards 48-volt electrical systems to support more powerful and efficient vehicles.

- Intelligent power management: Advanced algorithms will optimize power distribution based on real-time vehicle needs.

- Wireless diagnostics: Remote monitoring and troubleshooting of control module power circuits will become more common.

- Self-healing networks: Future wiring systems may be able to reroute power automatically in case of failures.

Staying informed about these advancements can help you make better decisions when maintaining or upgrading your vehicle.

Conclusion: Empowering Your Vehicle's Nervous System

The control module power circuit is the unsung hero of your vehicle's electrical system, quietly ensuring that all electronic components receive the power they need to function correctly. By understanding its components, recognizing common issues, and implementing preventive measures, you can significantly reduce the risk of electrical failures and keep your vehicle running smoothly.

Remember, a well-maintained control module power circuit not only enhances your vehicle's performance and reliability but also contributes to your safety on the road. Whether you're a DIY enthusiast or prefer to leave it to the professionals, regular attention to this critical system will pay dividends in the long run.

Stay proactive, stay informed, and keep your vehicle's brain powered up for the road ahead.

FAQs

- What is the main function of a control module power circuit?

It distributes power from the battery to various control modules, ensuring proper operation of vehicle systems. - How often should I check my vehicle's control module power circuit?

Perform a visual inspection monthly and have a professional check annually during routine maintenance. - Can a bad control module power circuit affect fuel efficiency?

Yes, it can lead to improper engine management, resulting in decreased fuel efficiency. - What's the most common cause of control module power circuit failures?

Voltage fluctuations due to battery or alternator issues are the most frequent culprits. - Is it safe to diagnose control module power circuit issues myself?

Basic checks are safe, but complex diagnostics should be left to professionals to avoid injury or damage.