Understanding the warning light symbols on your Yale forklift is crucial for maintaining safety, efficiency, and longevity of your equipment. This comprehensive guide will walk you through the most common warning lights you might encounter, their meanings, and the actions you should take when they illuminate. Whether you're a seasoned operator or new to the world of material handling, this information will help you keep your Yale forklift in top condition and ensure a safe working environment.

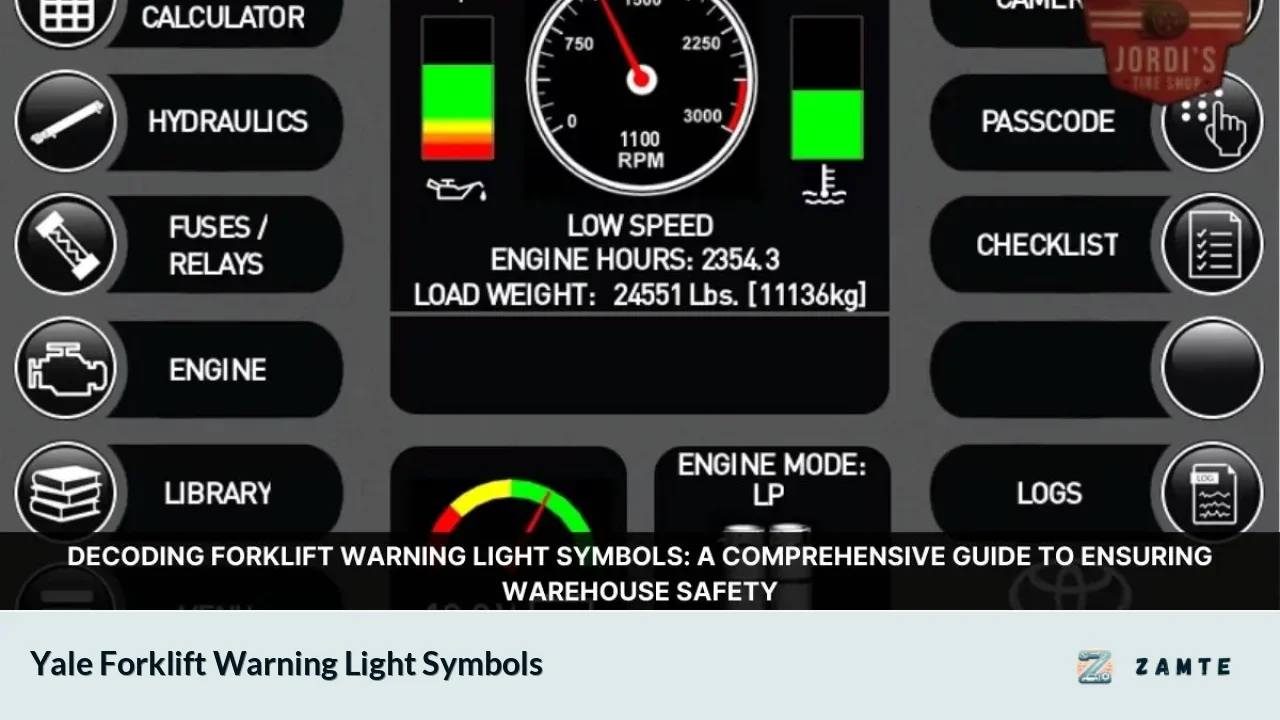

Yale Forklift Warning Light Symbols: Overview

Yale forklifts, like most modern industrial equipment, are equipped with a sophisticated system of warning lights and indicators. These lights are designed to alert operators to potential issues, from minor maintenance needs to critical safety concerns. Let's dive into the most important warning lights you need to know about.

| Warning Light | Color | Priority Level | Brief Meaning | Initial Action |

|---|---|---|---|---|

| Engine Oil Pressure | Red | High | Low engine oil pressure | Stop immediately and shut off engine |

| Engine Coolant Temperature | Red | High | Engine overheating | Stop and allow engine to cool |

| Battery Charge | Red | High | Charging system malfunction | Check alternator and connections |

| Check Engine | Yellow | Medium | Engine system issue detected | Seek maintenance, continue with caution |

| Transmission Temperature | Yellow | Medium | High transmission fluid temperature | Reduce load and monitor |

| Seat Belt | Blue | Low | Seat belt not fastened | Fasten seat belt before operation |

Engine Oil Pressure Warning Light

The engine oil pressure warning light is one of the most critical indicators on your Yale forklift. When this light illuminates, it signals that the engine's oil pressure has dropped below safe operating levels.

Causes:

- Low oil level

- Oil pump failure

- Clogged oil filter

- Worn engine bearings

Action Required: If this light comes on while operating, you should immediately stop the forklift and shut off the engine. Continuing to run the engine with low oil pressure can cause severe damage.

Potential Costs: Ignoring this warning could lead to complete engine failure, with repair costs potentially exceeding $5,000 to $10,000.

Professional Help: This issue requires immediate attention from a qualified technician. Do not attempt to operate the forklift until the problem is resolved.

"The engine oil pressure light is not something to be taken lightly. I've seen operators ignore it and end up with seized engines. Always treat it as an emergency."

Engine Coolant Temperature Warning Light

The engine coolant temperature warning light indicates that your forklift's engine is overheating. This is a serious condition that requires immediate attention.

Causes:

- Low coolant level

- Faulty thermostat

- Damaged water pump

- Clogged radiator

Action Required: If this light comes on, stop the forklift in a safe location and allow the engine to idle for a few minutes before shutting it off. Do not open the radiator cap until the engine has cooled completely.

Potential Costs: Overheating can cause severe engine damage. Repairs can range from $500 for minor issues to over $5,000 for major damage.

Professional Help: While you can check and top up coolant levels, persistent overheating issues should be addressed by a professional mechanic.

Battery Charge Warning Light

The battery charge warning light indicates a problem with the forklift's charging system. This could be due to issues with the alternator, battery, or connecting cables.

Causes:

- Faulty alternator

- Loose or corroded battery connections

- Worn drive belt

- Failing battery

Action Required: If this light comes on while operating, you may be able to finish your current task, but you should seek maintenance as soon as possible. The forklift may stop running if the battery depletes completely.

Potential Costs: Repairs can range from $100 for a new drive belt to $500 or more for a new alternator or battery.

Professional Help: While checking connections is a simple task, diagnosing and repairing charging system issues often requires professional assistance.

Check Engine Warning Light

The check engine warning light is a general indicator that the engine control unit has detected an issue. This can range from minor problems to more serious concerns.

Causes:

- Faulty sensors

- Emission control issues

- Fuel system problems

- Ignition system malfunctions

Action Required: When this light appears, you can typically continue operating the forklift, but you should schedule a maintenance check as soon as possible.

Potential Costs: Costs can vary widely depending on the underlying issue, ranging from $100 for a simple sensor replacement to $1,000 or more for major repairs.

Professional Help: Diagnosing check engine lights requires specialized diagnostic equipment. Always consult with a qualified technician.

"Don't ignore the check engine light just because the forklift seems to be running fine. It could be masking a problem that will become much more expensive if left unchecked."

Transmission Temperature Warning Light

The transmission temperature warning light indicates that the transmission fluid is overheating. This can lead to premature wear and damage to the transmission if not addressed.

Causes:

- Low transmission fluid

- Overloading the forklift

- Faulty transmission cooler

- Internal transmission problems

Action Required: If this light illuminates, reduce the load on the forklift and try to operate in a lower gear if possible. If the light persists, stop operation and allow the transmission to cool.

Potential Costs: Transmission repairs can be expensive, ranging from $500 for minor issues to over $3,000 for major repairs or replacement.

Professional Help: While checking fluid levels can be done by operators, diagnosing and repairing transmission issues should be left to professionals.

Seat Belt Indicator Light

The seat belt indicator light is a safety reminder to fasten your seat belt before operating the forklift.

Causes:

- Unfastened seat belt

- Faulty seat belt sensor

Action Required: Always fasten your seat belt before operating the forklift. If the light remains on even when the belt is fastened, there may be an issue with the sensor.

Potential Costs: Replacing a faulty seat belt sensor typically costs between $100 and $300.

Professional Help: While fastening the seat belt is a simple operator task, persistent issues with the indicator should be checked by a technician.

Additional Yale Forklift Warning Lights

Yale forklifts may have additional warning lights depending on the model and features. Some of these include:

- Parking Brake Indicator: Illuminates when the parking brake is engaged.

- Fuel Level Warning: Indicates low fuel level in combustion engine forklifts.

- DEF (Diesel Exhaust Fluid) Level Warning: For diesel forklifts, indicates low DEF level.

- Hydraulic Oil Temperature: Warns of overheating hydraulic oil.

- Operator Presence System: Indicates the operator is not properly seated.

Always refer to your specific Yale forklift model's operator manual for a complete list of warning lights and their meanings.

Importance of Regular Maintenance

Many warning light issues can be prevented through regular maintenance. Yale recommends following a strict maintenance schedule, which typically includes:

- Daily pre-shift inspections

- Regular oil and filter changes

- Scheduled hydraulic system maintenance

- Periodic electrical system checks

- Annual comprehensive inspections

By adhering to these schedules, you can reduce downtime, extend the life of your forklift, and ensure safer operation.

Conclusion

Understanding and responding appropriately to Yale forklift warning light symbols is crucial for safe and efficient operation. While some indicators may signal minor issues, others require immediate action to prevent serious damage or safety hazards. Always prioritize safety, follow your training, and consult your operator's manual when in doubt. Regular maintenance and prompt attention to warning lights will help keep your Yale forklift running smoothly and safely for years to come.

FAQs

- What should I do if multiple warning lights come on at once?

If multiple warning lights illuminate simultaneously, it's best to stop operation immediately and seek professional assistance. This could indicate a serious issue affecting multiple systems. - Can I reset warning lights on my Yale forklift myself?

While some minor warnings may reset themselves after addressing the issue, it's generally not recommended to reset warning lights without diagnosing and fixing the underlying problem. Always consult a qualified technician. - How often should I expect to see warning lights during normal operation?

During normal operation and with proper maintenance, warning lights should rarely illuminate. Frequent warnings could indicate underlying issues that need attention. - Are Yale forklift warning lights the same across all models?

While many warning lights are standard across models, there can be variations, especially in newer or more specialized models. Always refer to your specific model's operator manual for accurate information. - What's the difference between red and yellow warning lights?

Generally, red lights indicate critical issues requiring immediate attention, while yellow lights suggest caution and the need for monitoring or near-future maintenance.